why my spraying pressure is less than 100bar

Airless paint sprayers could always generate the high pressure for spraying the paint / coating / latex / emulsion / acrylic / primer / …..

normally the maximum pressure for the machine is over 200bar, but when you start to spray (active the airless spray gun trigger), the pressure will go down to 150bar or so. the spraying pressure will be different based on the working condition and enviroment.

if the pressure is over 100bar, then the machine could spray most of the paint without problem.

but if the pressure is less than 100bar, it will be too low to atomize the material. we need to check the machine by below steps:

1. Check the spray tips

did you use the correct airless spray gun tip size? (each machine has its own maximum tip size, this tip size is based on the sprayer’s pumping out capacity. the bigger output volume per minute, then the bigger tip size is available to support)

is the tip worn or not? (the lifetime for the airless spray tips is normally 4000 – 5000 square meters. so you need to change to a new tip after 4000 m2. otherwise the tip orifice is worn bigger which will get the pressure lower sameway)

2. Check the fluid leakage

power on the machine, and leave it in the maximum pressure (for example. 210bar),

is there any fluid leakage during the fluid passing way? for example, leak from the spray gun, hose, connector, or prime tube?

the sprayer is totally enclosed, the fluid is inside the tube / hose / gun / machine, there shouldn’t be any leakage.

if there’s leaking from the hose / gun / tip / spay gun tip guard / connectors, please fasten it or replace it.

if there’s leaking from the prime tube, there’s problem with the Prime / Spray Valve. please tighten the valve, or replace it.

3. Check the air leakage.

The whole fluid passing way should be no air entering inside. if the air go inside, the high pressure couldn’t be generated.

normally the air could go inside from the below parts.

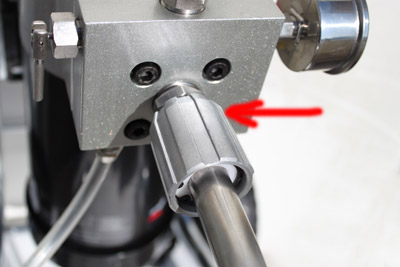

especially from the suction tube

there’s one black gasket / washer inside the suction tube, this washer is for sealing the air. so you must screw the tube tightenly.

there’s one black gasket / washer inside the suction tube, this washer is for sealing the air. so you must screw the tube tightenly.

4. Inlet valve / Suction valve damaged.

Inspection:The machine running normally (suction normally, prime normally, and the pressure go up quickly when you change the PRIME VALVE from Prime to Spray), but the pressure will drop down after spraying for several seconds.

Please turn the prime/sprayvalve to PRIME position and remove the

suction hose, pour the water into the inlet valve to check if it will blow out the water.

if the water can’t be blew out, then it means the inlet valve was worn.

Solutions:Replace the inlet valve.

5. Outlet valve damaged

5. Outlet valve damaged

Inspection: It takes longer time than normal for the machine to prime, or the machine

suck the paint and build up pressure normally, but the pressure was lower when spraying,

when stopped spraying and pressure back to normal.

please remove the suction hose, and push the spring nut of the inlet valve by tools or by hand, to check if pressuring is going down.

if the pressure goes down, it means the outlet valve was worn.

if the pressure doesn’t change, then the outlet valve is ok, you don’t need to change it.

6. the front pump body was worn by the high pressure fluid

The thread of the outlet valve on the front pump body is damage.

Inspection: The machine running normally, and the pressure is dropping when spraying,

please remove the outlet valve, and check the thread inside was cutted or broken by the high pressure fluid.

if yes, then please change the front pump body.

7. Diaphragm damaged.

7. Diaphragm damaged.

Inspection: Diaphragm is easily damaged parts, the machine suck paint, prime, build up

pressure normally, after eliminating all the above potential problems. Then check that if

the diaphragm is worn or deformed.

Motor power 1000w

Max. tip size 0.021"

Flow rate 1.8L/min

motor-power 1500W

max-tip-size 0.023"

flow-rate 2.5L/min

motor-power 1000W

max-tip-size 0.021"

flow-rate 2.0L/min